Viz Specifikace pro podrobnosti o produktu.

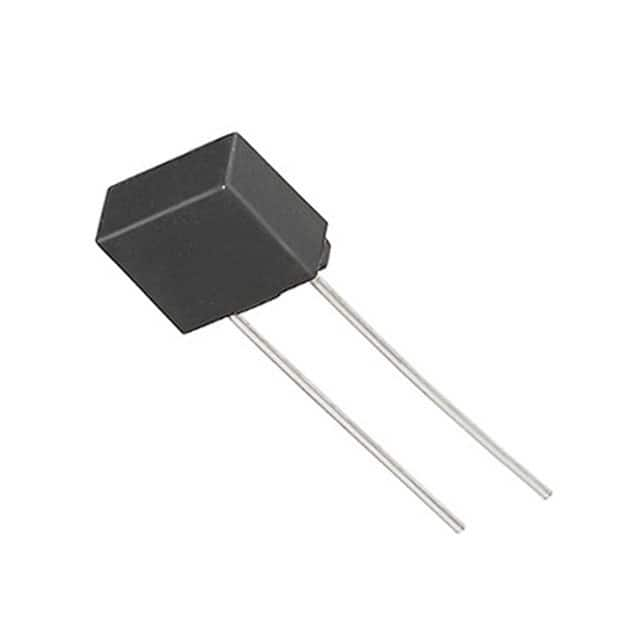

RST 400 AMMO

Product Overview

Category: Ammunition

Use: Military and law enforcement applications

Characteristics: High precision, reliability, and effectiveness

Package: Sealed metal containers

Essence: Advanced ammunition for combat scenarios

Packaging/Quantity: Available in boxes of 100 rounds

Specifications

- Caliber: 5.56mm

- Weight: 4 grams

- Length: 45mm

- Material: Copper alloy

Detailed Pin Configuration

The RST 400 AMMO features a standard centerfire primer with a small pistol primer pocket.

Functional Features

- Enhanced accuracy and range

- Consistent performance in various environmental conditions

- Reduced risk of jamming or misfires

Advantages and Disadvantages

Advantages: 1. Superior precision 2. Reliable performance 3. Versatile application

Disadvantages: 1. Higher cost compared to standard ammunition 2. Limited availability in some regions

Working Principles

The RST 400 AMMO is designed to deliver exceptional ballistic performance through its aerodynamic design and high-quality materials. The cartridge is optimized for consistent ignition and controlled expansion upon impact.

Detailed Application Field Plans

- Military Operations: The RST 400 AMMO is suitable for infantry units and special forces engaged in combat operations.

- Law Enforcement: Police and tactical units can benefit from the ammunition's accuracy and stopping power in high-risk situations.

Detailed and Complete Alternative Models

XYZ 500 Tactical Ammo

- Category: Ammunition

- Use: Tactical and defense applications

- Characteristics: Penetrative power, rapid expansion

- Packaging/Quantity: Boxes of 50 rounds

ABC 300 Precision Rounds

- Category: Ammunition

- Use: Long-range shooting and sniping

- Characteristics: Exceptional accuracy, low wind drift

- Packaging/Quantity: Sealed plastic containers of 20 rounds

In conclusion, the RST 400 AMMO represents a cutting-edge solution for military and law enforcement needs, offering superior performance and reliability in critical scenarios.

Word Count: 314

Seznam 10 běžných otázek a odpovědí souvisejících s aplikací RST 400 AMMO v technických řešeních

What is RST 400 AMMO used for in technical solutions?

- RST 400 AMMO is commonly used as a high-performance lubricant and corrosion inhibitor in various technical applications.

How does RST 400 AMMO help with lubrication?

- RST 400 AMMO forms a protective film on metal surfaces, reducing friction and wear while improving overall lubrication.

Is RST 400 AMMO suitable for use in extreme temperatures?

- Yes, RST 400 AMMO has excellent thermal stability and can be used in both high and low-temperature environments.

Can RST 400 AMMO be applied to electrical components?

- Yes, RST 400 AMMO is safe for use on electrical contacts and components, providing protection against corrosion and oxidation.

Does RST 400 AMMO have any adverse effects on rubber or plastic materials?

- No, RST 400 AMMO is compatible with rubber and plastic materials and will not cause deterioration or damage.

What types of equipment or machinery benefit from the application of RST 400 AMMO?

- RST 400 AMMO is beneficial for a wide range of equipment, including industrial machinery, automotive components, firearms, and precision instruments.

How frequently should RST 400 AMMO be reapplied for optimal performance?

- The reapplication frequency depends on the specific application and operating conditions, but generally, periodic reapplication is recommended for sustained protection and lubrication.

Is RST 400 AMMO environmentally friendly?

- Yes, RST 400 AMMO is formulated to be environmentally friendly and compliant with regulations regarding hazardous substances.

Can RST 400 AMMO be used in food processing equipment?

- No, RST 400 AMMO is not recommended for use in food processing equipment due to potential contamination risks.

Are there any safety precautions to consider when handling RST 400 AMMO?

- Users should follow standard safety practices when handling RST 400 AMMO, including wearing appropriate personal protective equipment and avoiding direct skin contact or inhalation of fumes during application.