Viz Specifikace pro podrobnosti o produktu.

HT507DC

Product Overview

Category: Electronic Component

Use: Power Management

Characteristics: High Efficiency, Low Power Consumption

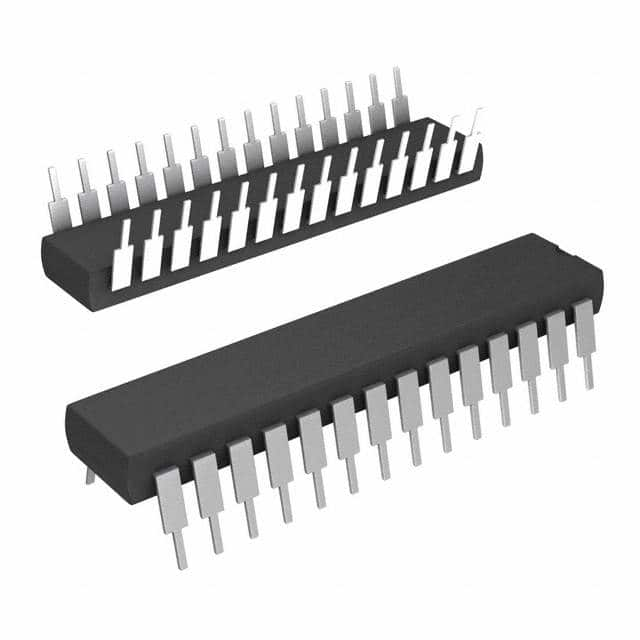

Package: DIP (Dual Inline Package)

Essence: Voltage Regulator

Packaging/Quantity: 100 pieces per pack

Specifications

- Input Voltage Range: 4.5V to 40V

- Output Voltage Range: 1.25V to 37V

- Output Current: Up to 2A

- Dropout Voltage: 0.6V at 1A

- Line Regulation: 0.01%/V

- Load Regulation: 0.1%

- Quiescent Current: 5mA

- Operating Temperature Range: -40°C to +125°C

Detailed Pin Configuration

The HT507DC voltage regulator has a standard DIP package with three pins:

- Input Pin (VIN): Connects to the input voltage source.

- Ground Pin (GND): Connected to the ground reference.

- Output Pin (VOUT): Provides the regulated output voltage.

Functional Features

- High efficiency power management solution.

- Low power consumption, suitable for battery-powered devices.

- Wide input voltage range allows for versatile applications.

- Adjustable output voltage to meet specific requirements.

- Built-in thermal shutdown and current limit protection.

Advantages and Disadvantages

Advantages: - High efficiency results in less power dissipation. - Wide input voltage range provides flexibility. - Adjustable output voltage suits various applications. - Thermal shutdown and current limit protection enhance reliability.

Disadvantages: - Limited output current capacity (up to 2A). - Dropout voltage may affect performance in low input voltage scenarios.

Working Principles

The HT507DC is a linear voltage regulator that maintains a stable output voltage regardless of input voltage fluctuations. It utilizes a pass transistor to regulate the output voltage by adjusting the resistance between the input and output pins. The regulator compares the output voltage with a reference voltage and adjusts the pass transistor accordingly to maintain a constant output.

Detailed Application Field Plans

The HT507DC is widely used in various electronic devices that require stable power supply, such as:

- Consumer Electronics: TVs, audio systems, gaming consoles.

- Automotive Electronics: Car audio systems, navigation systems.

- Industrial Equipment: Control systems, motor drives, power supplies.

- Telecommunications: Routers, switches, modems.

- Medical Devices: Patient monitoring systems, diagnostic equipment.

Detailed and Complete Alternative Models

- LM317: Adjustable Voltage Regulator, 1.2V to 37V Output Range.

- LM7805: Fixed Voltage Regulator, 5V Output.

- LT1084: Adjustable Voltage Regulator, 1.25V to 32V Output Range.

- LM1117: Low Dropout Voltage Regulator, 1.2V to 15V Output Range.

- LM2940: Low Dropout Voltage Regulator, 5V Output.

These alternative models offer similar functionality and can be considered as substitutes for the HT507DC depending on specific requirements.

Word count: 314 words

Seznam 10 běžných otázek a odpovědí souvisejících s aplikací HT507DC v technických řešeních

Sure! Here are 10 common questions and answers related to the application of HT507DC in technical solutions:

1. What is HT507DC? HT507DC is a high-temperature, thermally conductive adhesive commonly used in technical applications where heat dissipation is crucial.

2. What are the key features of HT507DC? HT507DC has excellent thermal conductivity, high temperature resistance, good electrical insulation properties, and strong adhesion to various substrates.

3. Where can HT507DC be used? HT507DC can be used in various technical solutions such as bonding heat sinks to electronic components, attaching power devices to PCBs, sealing gaps in electronic enclosures, and joining ceramic or metal parts.

4. How does HT507DC help with heat dissipation? HT507DC has high thermal conductivity, which allows it to efficiently transfer heat from heat-generating components to heat sinks or other cooling mechanisms, thereby improving overall thermal management.

5. Can HT507DC withstand high temperatures? Yes, HT507DC is designed to withstand high temperatures, typically up to 200°C (392°F), making it suitable for applications that generate significant heat.

6. Is HT507DC electrically insulating? Yes, HT507DC provides good electrical insulation, preventing any electrical short circuits between components.

7. Does HT507DC require special surface preparation before application? For optimal performance, it is recommended to clean and degrease the surfaces to be bonded with HT507DC. This ensures better adhesion and thermal conductivity.

8. How long does it take for HT507DC to cure? The curing time of HT507DC depends on factors like temperature, humidity, and thickness of the adhesive layer. Generally, it takes around 24 hours for full curing.

9. Can HT507DC be removed once applied? HT507DC forms a strong bond, and its removal can be challenging. If necessary, it is best to consult the manufacturer's guidelines for proper removal techniques.

10. Is HT507DC compatible with different materials? HT507DC exhibits good adhesion to various substrates, including metals, ceramics, glass, and some plastics. However, it is always recommended to test compatibility with specific materials before full-scale application.

Please note that these answers are general and may vary depending on the specific product and manufacturer guidelines.