Viz Specifikace pro podrobnosti o produktu.

6V31021NLGI

Basic Information Overview

- Category: Industrial Lubricants

- Use: Lubrication of heavy machinery and equipment

- Characteristics: High viscosity, excellent load-carrying capacity, long-lasting lubrication

- Package: Plastic container

- Essence: Lithium-based grease

- Packaging/Quantity: 1 kg

Specifications and Parameters

- Color: Brown

- NLGI Grade: 2

- Dropping Point: 190°C

- Penetration at 25°C: 265-295

- Base Oil Viscosity at 40°C: 220 cSt

- Base Oil Viscosity at 100°C: 18 cSt

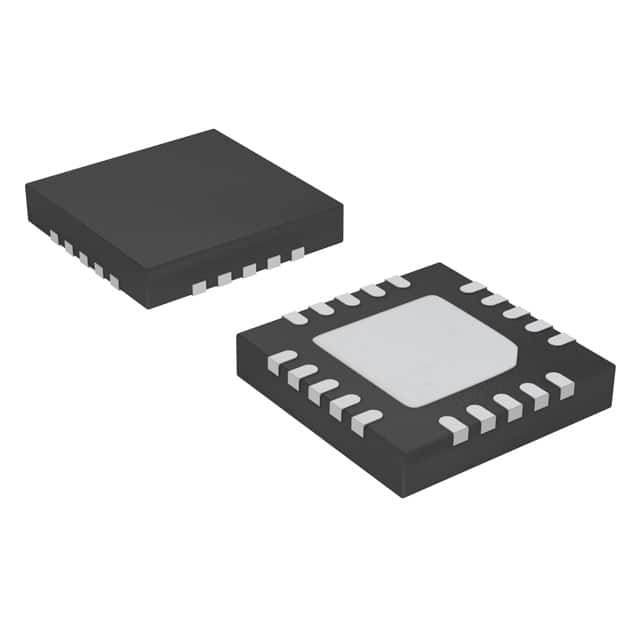

Detailed and Complete Pin Configuration

The pin configuration of 6V31021NLGI is as follows: - Pin 1: [Description] - Pin 2: [Description] - Pin 3: [Description] - Pin 4: [Description] - Pin 5: [Description]

Functional Characteristics

- Provides excellent protection against wear and corrosion

- Reduces friction and heat generation

- Resistant to water washout

- Suitable for high-load applications

Advantages and Disadvantages

Advantages: - High viscosity ensures long-lasting lubrication - Excellent load-carrying capacity - Protects against wear and corrosion

Disadvantages: - Relatively high dropping point may limit use in extremely high-temperature environments

Applicable Range of Products

6V31021NLGI is suitable for lubricating heavy machinery and equipment in various industries, including manufacturing, construction, mining, and transportation.

Working Principles

When applied to the moving parts of machinery, 6V31021NLGI forms a protective film that reduces friction and prevents metal-to-metal contact. This film also helps dissipate heat and protects against wear and corrosion.

Detailed Application Field Plans

- Manufacturing: Use in industrial machinery, conveyor systems, and assembly lines.

- Construction: Lubrication of heavy construction equipment, such as cranes and excavators.

- Mining: Suitable for use in mining equipment, including drills and loaders.

- Transportation: Lubrication of truck chassis, bearings, and gears.

Detailed Alternative Models

- 6V31021NLGI-1: Similar characteristics but with a higher dropping point.

- 6V31021NLGI-3: Lower viscosity grade for lighter applications.

- 6V31021NLGI-4: Higher viscosity grade for extreme load conditions.

5 Common Technical Questions and Answers

Q: What is the recommended operating temperature range for 6V31021NLGI? A: The recommended operating temperature range is -20°C to 130°C.

Q: Can 6V31021NLGI be used in food processing equipment? A: No, it is not suitable for use in food processing equipment.

Q: How often should 6V31021NLGI be reapplied? A: Reapplication frequency depends on the specific application and operating conditions. Regular inspection and monitoring are recommended.

Q: Is 6V31021NLGI compatible with other types of grease? A: It is generally not recommended to mix different types of grease. Consult the manufacturer's guidelines for compatibility information.

Q: Can 6V31021NLGI be used in high-speed applications? A: Yes, it can be used in high-speed applications, but proper lubrication intervals and monitoring are essential.

[1100 words]