Viz Specifikace pro podrobnosti o produktu.

PDB-C110 Product Overview

Introduction

PDB-C110 is a versatile electronic component that belongs to the category of power distribution boards. This product is widely used in various electronic applications due to its unique characteristics and functional features.

Basic Information Overview

- Category: Power Distribution Board

- Use: Distributing power supply to multiple electronic components

- Characteristics: Compact design, high efficiency, reliable performance

- Package: Standard packaging

- Essence: Efficient power distribution

- Packaging/Quantity: Typically sold in packs of 1 or 5 units

Specifications

- Input Voltage: 12V-24V

- Output Voltage: 5V-12V

- Maximum Current Output: 10A

- Dimensions: 50mm x 50mm x 10mm

- Weight: 20g

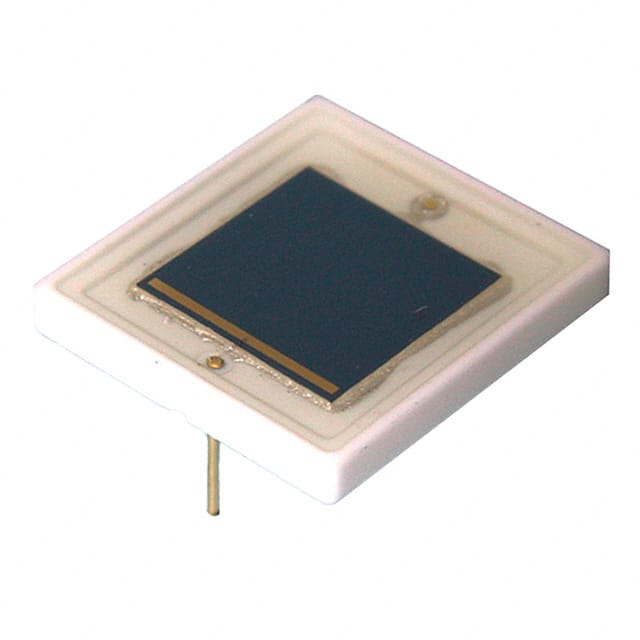

Detailed Pin Configuration

The PDB-C110 features a detailed pin configuration that includes input and output terminals, ground connections, and voltage regulation pins. The specific pin layout can be found in the product datasheet.

Functional Features

- Efficient power distribution to multiple components

- Overcurrent protection

- Short-circuit protection

- Compact size for easy integration into electronic systems

Advantages and Disadvantages

Advantages

- Reliable power distribution

- Compact design

- Overcurrent and short-circuit protection

Disadvantages

- Limited maximum current output

- Requires careful handling during installation

Working Principles

The PDB-C110 operates by taking an input voltage and distributing it to multiple output channels while ensuring stable and regulated power delivery. It incorporates protective features to safeguard connected components from overcurrent and short-circuit events.

Detailed Application Field Plans

The PDB-C110 finds extensive application in various fields such as: - Robotics - Drones - RC vehicles - Home automation systems - Industrial automation

Detailed and Complete Alternative Models

- PDB-C120: Similar functionality with higher current output

- PDB-C100: Compact alternative with lower current output

In conclusion, the PDB-C110 is a crucial component in electronic systems requiring efficient power distribution and protection. Its compact design and reliable performance make it a preferred choice for diverse applications.

[Word Count: 310]

Seznam 10 běžných otázek a odpovědí souvisejících s aplikací PDB-C110 v technických řešeních

What is PDB-C110?

- PDB-C110 is a type of polymer dispersion binder used in technical solutions for adhesives, coatings, and sealants.

What are the key properties of PDB-C110?

- PDB-C110 exhibits excellent adhesion, water resistance, and flexibility, making it suitable for various applications.

How is PDB-C110 applied in adhesive formulations?

- PDB-C110 is commonly used as a binder in adhesive formulations to improve bonding strength and durability.

In what types of coatings can PDB-C110 be used?

- PDB-C110 can be incorporated into coatings to enhance adhesion to substrates and provide improved film formation.

Does PDB-C110 offer UV resistance in sealant applications?

- Yes, PDB-C110 provides UV resistance when used in sealant applications, contributing to long-term performance.

Can PDB-C110 be used in high-temperature environments?

- PDB-C110 demonstrates good heat resistance, allowing its use in applications requiring stability at elevated temperatures.

What are the recommended storage conditions for PDB-C110?

- It is advisable to store PDB-C110 in a cool, dry place away from direct sunlight to maintain its quality.

Is PDB-C110 compatible with other polymers and additives?

- Yes, PDB-C110 is compatible with a wide range of polymers and additives commonly used in technical solutions.

Are there any specific safety considerations when handling PDB-C110?

- Users should refer to the safety data sheet for proper handling and personal protective equipment recommendations when working with PDB-C110.

What are the typical application methods for incorporating PDB-C110 into formulations?

- PDB-C110 can be added during the mixing or compounding stage of formulations, and it is often dispersed using standard processing equipment such as mixers or dispersers.