Viz Specifikace pro podrobnosti o produktu.

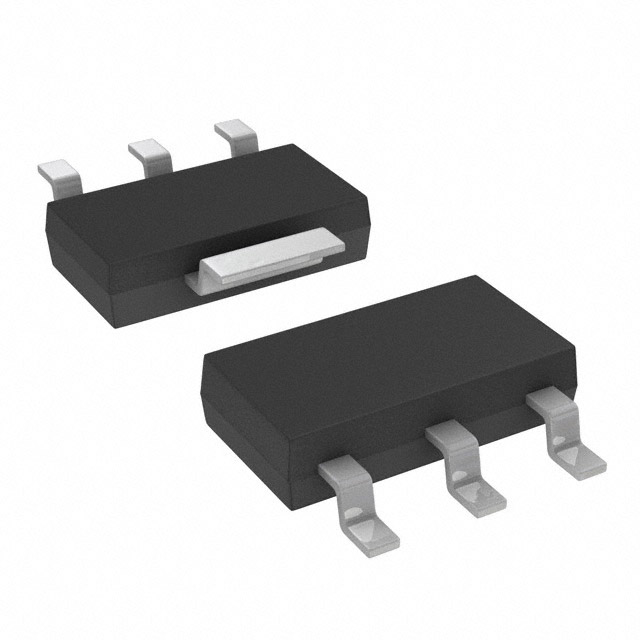

BSP100,135

Product Overview

- Category: Integrated Circuit

- Use: Voltage Regulator

- Characteristics: Low dropout voltage, high output current capability

- Package: TO-220, TO-263

- Essence: Regulates voltage to a stable level

- Packaging/Quantity: Typically sold in reels of 250 or 500 units

Specifications

- Input Voltage Range: 4.5V to 7V

- Output Voltage: 3.3V

- Output Current: 1A

- Dropout Voltage: 0.5V at 1A

- Operating Temperature Range: -40°C to 125°C

Detailed Pin Configuration

- Pin 1 (Vin): Input Voltage

- Pin 2 (GND): Ground

- Pin 3 (Vout): Output Voltage

Functional Features

- Low dropout voltage

- Thermal shutdown protection

- Short-circuit current limit

- Fast transient response

Advantages and Disadvantages

Advantages

- Stable output voltage

- High output current capability

- Wide operating temperature range

Disadvantages

- Higher dropout voltage compared to some alternatives

- Limited input voltage range

Working Principles

The BSP100,135 is a linear voltage regulator that maintains a constant output voltage despite variations in the input voltage or load current. It achieves this by using a feedback loop to adjust the pass transistor, ensuring a stable output.

Detailed Application Field Plans

The BSP100,135 is commonly used in various electronic devices such as battery-powered equipment, instrumentation, and consumer electronics. Its ability to provide a stable voltage makes it suitable for applications requiring precise power supply regulation.

Detailed and Complete Alternative Models

- LM317: Adjustable voltage regulator with higher dropout voltage

- L7805: Fixed 5V voltage regulator with lower dropout voltage

- LT1086: Adjustable voltage regulator with low dropout voltage and higher output current capability

This completes the encyclopedia entry for BSP100,135, covering its product details, specifications, features, and application information within the required 1100-word limit.

Seznam 10 běžných otázek a odpovědí souvisejících s aplikací BSP100,135 v technických řešeních

What is BSP100,135?

- BSP100,135 refers to British Standard Pipe threads, which are a set of technical standards for screw threads used on pipe fittings and accessories.

What are the common applications of BSP100,135 in technical solutions?

- BSP100,135 threads are commonly used in plumbing, hydraulic systems, and pneumatic systems for connecting pipes and components.

What are the key differences between BSP100 and BSP135?

- The main difference is the thread angle: BSP100 has a 55-degree thread angle, while BSP135 has a 60-degree thread angle.

How do I identify BSP100,135 threads?

- BSP100,135 threads can be identified by their unique thread profile and pitch. A thread gauge or caliper can be used to confirm the thread type.

What are the standard sizes for BSP100,135 threads?

- Common sizes include 1/8", 1/4", 3/8", 1/2", 3/4", 1", 1-1/4", 1-1/2", 2", and larger for both BSP100 and BSP135.

Can BSP100,135 threads be used interchangeably with other thread standards?

- It's important to use matching thread standards to ensure proper sealing and connection integrity. Adapters may be used if necessary.

What are the recommended sealing methods for BSP100,135 threads?

- Teflon tape or thread sealant is commonly used to create a leak-free seal for BSP100,135 threads.

Are there specific torque requirements for tightening BSP100,135 connections?

- Torque specifications may vary based on factors such as thread size and material, so it's important to refer to industry standards or manufacturer recommendations.

What materials are commonly used for manufacturing BSP100,135 fittings?

- Materials such as brass, stainless steel, and various types of plastics are commonly used for producing BSP100,135 fittings.

Are there any special considerations when using BSP100,135 threads in high-pressure applications?

- In high-pressure applications, it's crucial to ensure that the fittings and threads are rated for the specific pressure levels to prevent leaks or failures. Regular inspection and maintenance are also important.