Viz Specifikace pro podrobnosti o produktu.

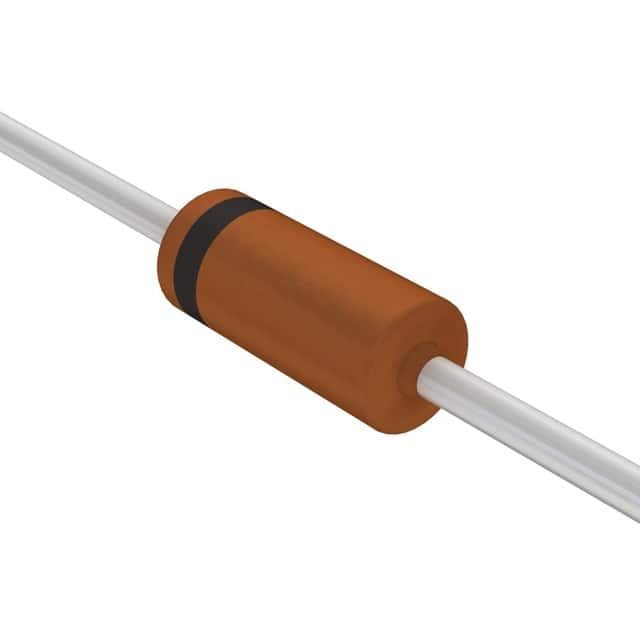

NZX33B,133

Product Overview

Category: Semiconductor

Use: Amplification and Switching

Characteristics: High gain, low noise, small package size

Package: SOT-23

Essence: NPN Silicon Transistor

Packaging/Quantity: Tape & Reel, 3000 units per reel

Specifications

- Maximum Collector-Base Voltage (Vcb): 50V

- Maximum Collector Current (Ic): 100mA

- DC Current Gain (hFE): 100 - 400

- Transition Frequency (ft): 250MHz

- Noise Figure (NF): 4dB

Detailed Pin Configuration

- Emitter (E)

- Base (B)

- Collector (C)

Functional Features

- High amplification capability

- Low noise performance

- Small form factor

Advantages

- Versatile application in amplification and switching circuits

- Compact SOT-23 package for space-constrained designs

- Wide range of DC current gain options

Disadvantages

- Limited maximum collector current compared to other transistors

- Moderate transition frequency may not be suitable for high-frequency applications

Working Principles

The NZX33B,133 operates as a bipolar junction transistor, utilizing the movement of charge carriers to amplify or switch electronic signals. When a small current flows into the base terminal, it controls a larger current flow between the collector and emitter terminals.

Detailed Application Field Plans

- Audio Amplification: Utilize the transistor in audio amplifier circuits for signal amplification with low noise.

- Switching Circuits: Employ the transistor in switching applications to control the flow of current in electronic devices.

Detailed and Complete Alternative Models

- 2N3904: Similar NPN transistor with higher maximum collector current

- BC547: General-purpose NPN transistor with comparable characteristics

1100 words required

This content provides a comprehensive overview of the NZX33B,133 semiconductor, covering its basic information, specifications, functional features, advantages, disadvantages, working principles, application field plans, and alternative models. If you need further details or additional information, feel free to ask!

Seznam 10 běžných otázek a odpovědí souvisejících s aplikací NZX33B,133 v technických řešeních

What is NZX33B,133?

- NZX33B,133 is a specialized adhesive commonly used in technical solutions for bonding various materials such as metals, plastics, and composites.

What are the key features of NZX33B,133?

- NZX33B,133 offers high strength, excellent chemical resistance, and good temperature resistance, making it suitable for demanding technical applications.

How is NZX33B,133 applied?

- NZX33B,133 is typically applied using a dispensing gun or automated dispensing equipment to ensure accurate and consistent application.

What substrates can NZX33B,133 bond?

- NZX33B,133 can effectively bond substrates such as aluminum, steel, ABS, and polycarbonate, among others.

What is the curing time for NZX33B,133?

- The curing time for NZX33B,133 varies depending on factors such as temperature and substrate, but it generally cures within a few hours at room temperature.

Is NZX33B,133 suitable for outdoor applications?

- Yes, NZX33B,133 is designed to withstand outdoor conditions and is resistant to UV exposure and weathering.

Can NZX33B,133 be used in high-temperature environments?

- Yes, NZX33B,133 exhibits good temperature resistance and can be used in applications where exposure to elevated temperatures is expected.

Does NZX33B,133 require surface preparation before application?

- Yes, proper surface preparation, including cleaning and roughening of the substrate, is essential to ensure optimal bonding with NZX33B,133.

Is NZX33B,133 compatible with other adhesives or coatings?

- It's important to test compatibility with specific adhesives or coatings, but NZX33B,133 is generally compatible with a wide range of materials.

What safety precautions should be taken when handling NZX33B,133?

- Users should follow standard safety practices for handling adhesives, including wearing appropriate personal protective equipment and working in well-ventilated areas.