Viz Specifikace pro podrobnosti o produktu.

E2K-L26MC1 Encyclopedia Entry

Product Overview

Category

The E2K-L26MC1 belongs to the category of inductive proximity sensors.

Use

It is used for non-contact detection of metallic objects.

Characteristics

- Sensing Distance: 2.6mm

- Output Configuration: NPN

- Housing Material: Nickel-plated brass

- Connection Method: Pre-wired (2m)

- Operating Voltage: 10-30V DC

Package

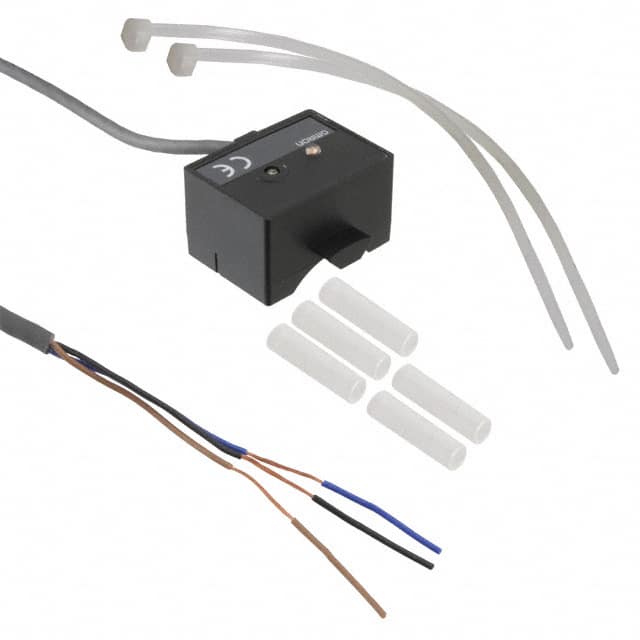

The E2K-L26MC1 comes in a compact, cylindrical housing with a pre-wired connection for easy installation.

Essence

This sensor provides reliable and accurate detection of metallic objects in various industrial applications.

Packaging/Quantity

The E2K-L26MC1 is typically packaged individually.

Specifications

- Sensing Distance: 2.6mm ±10%

- Standard Object: Iron, 8×8×1mm

- Power Supply Voltage: 10-30V DC

- Current Consumption: 10mA max.

- Control Output: NPN

- Operation Indicator: Red LED

- Protection Structure: IP67

Detailed Pin Configuration

The E2K-L26MC1 has three pins: 1. Brown wire: Power supply (+) 2. Blue wire: Power supply (-) 3. Black wire: Control output

Functional Features

- High precision sensing of metallic objects

- Compact and durable design

- LED indicator for easy status monitoring

Advantages

- Reliable detection of metallic objects

- Compact size for easy integration

- Suitable for harsh industrial environments

Disadvantages

- Limited sensing distance

- Specific to metallic object detection only

Working Principles

The E2K-L26MC1 operates based on the principle of electromagnetic induction. When a metallic object enters its sensing range, it causes a change in the sensor's electromagnetic field, triggering the control output.

Detailed Application Field Plans

The E2K-L26MC1 is commonly used in the following applications: - Conveyor systems - Machine automation - Robotics - Material handling equipment

Detailed and Complete Alternative Models

Some alternative models to the E2K-L26MC1 include: - E2K-L15MC1: Similar inductive proximity sensor with a 1.5mm sensing distance - E2K-X4ME1: Capacitive proximity sensor for non-metallic object detection

In conclusion, the E2K-L26MC1 inductive proximity sensor offers reliable and precise detection of metallic objects in various industrial settings. Its compact design, high durability, and ease of integration make it a valuable component in automation and control systems.

Word Count: 410

Seznam 10 běžných otázek a odpovědí souvisejících s aplikací E2K-L26MC1 v technických řešeních

What is the E2K-L26MC1 sensor used for?

- The E2K-L26MC1 sensor is commonly used for detecting the presence or absence of an object in industrial automation applications.

What type of output does the E2K-L26MC1 sensor provide?

- The E2K-L26MC1 sensor provides a digital output, typically in the form of a voltage or current signal, to indicate the presence or absence of an object.

What is the sensing distance of the E2K-L26MC1 sensor?

- The E2K-L26MC1 sensor has a specified sensing distance of 26mm, which means it can detect objects within that range.

Can the E2K-L26MC1 sensor be used in harsh environments?

- Yes, the E2K-L26MC1 sensor is designed to withstand harsh industrial environments and is suitable for use in applications with dust, moisture, and vibration.

What are the typical applications of the E2K-L26MC1 sensor?

- Typical applications of the E2K-L26MC1 sensor include conveyor systems, packaging machinery, material handling equipment, and automated assembly lines.

Does the E2K-L26MC1 sensor require calibration?

- The E2K-L26MC1 sensor is factory calibrated and typically does not require user calibration under normal operating conditions.

Can the E2K-L26MC1 sensor detect non-metallic objects?

- Yes, the E2K-L26MC1 sensor can detect both metallic and non-metallic objects, making it versatile for various application requirements.

What power supply voltage does the E2K-L26MC1 sensor require?

- The E2K-L26MC1 sensor typically operates on a 12-24V DC power supply, making it compatible with standard industrial power systems.

Is the E2K-L26MC1 sensor easy to install?

- Yes, the E2K-L26MC1 sensor is designed for easy installation and integration into existing industrial systems, with mounting options and simple wiring connections.

Are there any special considerations for using the E2K-L26MC1 sensor in safety-critical applications?

- When used in safety-critical applications, it's important to follow relevant safety standards and guidelines to ensure proper functionality and reliability of the E2K-L26MC1 sensor.