Viz Specifikace pro podrobnosti o produktu.

SBR1545CT

Product Overview

Category

The SBR1545CT belongs to the category of Schottky Barrier Rectifiers.

Use

It is commonly used in power supply applications, inverters, and freewheeling diodes.

Characteristics

- High current capability

- Low forward voltage drop

- Fast switching speed

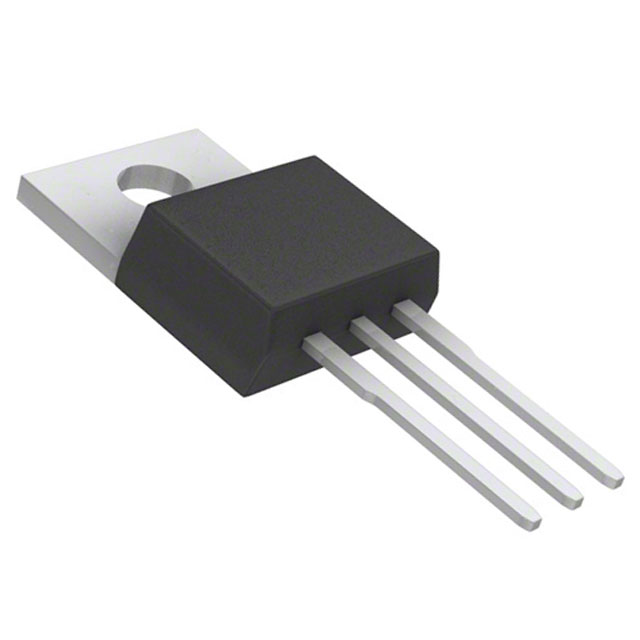

Package

The SBR1545CT is typically available in a TO-220AB package.

Essence

This rectifier is essential for converting alternating current (AC) to direct current (DC) efficiently.

Packaging/Quantity

It is usually packaged in reels or tubes, with quantities varying based on manufacturer specifications.

Specifications

- Maximum Average Forward Current: 15A

- Maximum Reverse Voltage: 45V

- Forward Voltage Drop: 0.55V at 7.5A

- Operating Temperature Range: -65°C to 175°C

Detailed Pin Configuration

The SBR1545CT has a standard TO-220AB pin configuration: 1. Anode 2. Cathode 3. Not connected (tab)

Functional Features

- Low power loss

- High efficiency

- High surge current capability

Advantages

- Reduced heat sink requirements

- Improved system efficiency

- Enhanced thermal performance

Disadvantages

- Higher cost compared to standard rectifiers

- Limited reverse voltage rating

Working Principles

The SBR1545CT operates based on the Schottky barrier principle, which involves the formation of a metal-semiconductor junction with low forward voltage drop and fast switching characteristics.

Detailed Application Field Plans

The SBR1545CT is widely used in: - Switching power supplies - DC-DC converters - Motor control circuits - Solar panel bypass diodes

Detailed and Complete Alternative Models

Some alternative models to the SBR1545CT include: - SBR2045CT - SBR3045CT - SBR4045CT

In conclusion, the SBR1545CT is a high-performance Schottky Barrier Rectifier with excellent characteristics suitable for various power supply and conversion applications.

[Word count: 287]

Seznam 10 běžných otázek a odpovědí souvisejících s aplikací SBR1545CT v technických řešeních

Sure, here are 10 common questions and answers related to the application of SBR1545CT in technical solutions:

Question: What is SBR1545CT?

Answer: SBR1545CT is a type of Styrene Butadiene Rubber (SBR) with a high styrene content, known for its excellent abrasion resistance and good aging properties.Question: What are the typical applications of SBR1545CT?

Answer: SBR1545CT is commonly used in tire treads, conveyor belts, industrial hoses, and other rubber products requiring high abrasion resistance.Question: How does SBR1545CT compare to other types of SBR?

Answer: SBR1545CT has a higher styrene content compared to other SBR grades, which contributes to its superior abrasion resistance and aging properties.Question: What are the key advantages of using SBR1545CT in technical solutions?

Answer: The key advantages include excellent abrasion resistance, good aging properties, and suitability for various rubber products in demanding applications.Question: Can SBR1545CT be used in outdoor applications?

Answer: Yes, SBR1545CT is suitable for outdoor applications due to its good weathering resistance and durability.Question: What processing methods are compatible with SBR1545CT?

Answer: SBR1545CT can be processed using methods such as extrusion, molding, and calendaring to manufacture a wide range of rubber products.Question: Does SBR1545CT require any special compounding ingredients?

Answer: SBR1545CT may benefit from the addition of reinforcing fillers, antioxidants, and processing aids to enhance its performance in specific applications.Question: What temperature range is SBR1545CT suitable for?

Answer: SBR1545CT exhibits good performance within a temperature range of -40°C to 100°C, making it suitable for both cold and moderately hot environments.Question: Is SBR1545CT compatible with other rubber materials?

Answer: SBR1545CT can be blended with other rubber compounds to achieve desired properties and performance characteristics in technical solutions.Question: Are there any specific guidelines for storing and handling SBR1545CT?

Answer: It is recommended to store SBR1545CT in a cool, dry place away from direct sunlight and sources of heat, and to follow standard safety precautions when handling the material.