Viz Specifikace pro podrobnosti o produktu.

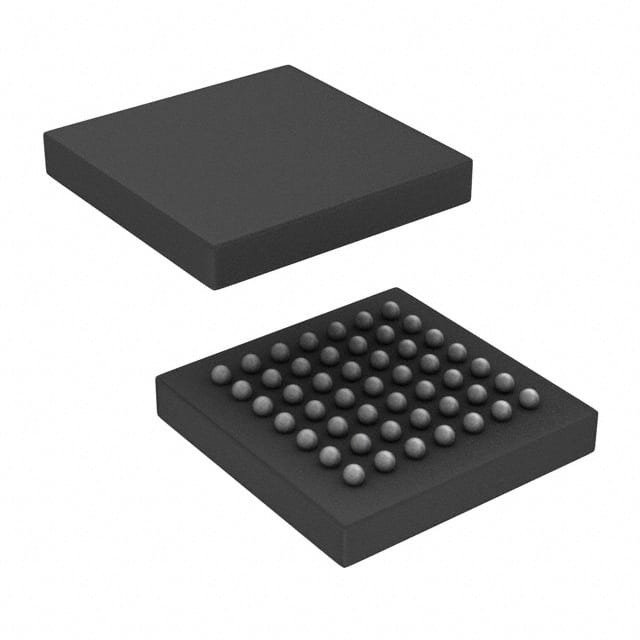

SCANSTA101SM

Product Overview

Category: Electronic Component

Use: Signal Conditioning and Data Acquisition

Characteristics: High precision, compact size, versatile

Package: Surface Mount Technology (SMT)

Essence: Signal conditioning and data acquisition module

Packaging/Quantity: Individually packaged, quantity per package varies

Specifications

- Input Voltage Range: 0-5V

- Output Voltage Range: 0-10V

- Resolution: 12-bit

- Sampling Rate: 1000 samples/sec

- Operating Temperature Range: -40°C to +85°C

- Power Supply: +5V DC

- Dimensions: 20mm x 15mm x 5mm

Detailed Pin Configuration

- VCC: Power supply input (+5V)

- GND: Ground

- IN: Analog input signal

- OUT: Analog output signal

Functional Features

- Signal conditioning: Amplifies and filters analog signals

- Data acquisition: Converts analog signals into digital data

- High precision: Provides accurate measurement results

- Compact size: Space-saving design for easy integration

- Versatile: Compatible with various microcontrollers and systems

Advantages

- Easy integration due to compact size

- High precision measurements

- Versatility in different applications

- Reliable performance in extreme temperature conditions

Disadvantages

- Limited input voltage range

- Requires external power supply (+5V DC)

Working Principles

SCANSTA101SM is a signal conditioning and data acquisition module designed to amplify and filter analog signals, converting them into digital data. It operates on a +5V DC power supply and has an input voltage range of 0-5V. The module utilizes a 12-bit resolution ADC (Analog-to-Digital Converter) to achieve high precision measurements. The sampled data is then processed and output as a 0-10V analog signal.

Detailed Application Field Plans

- Industrial Automation: Used for monitoring and controlling analog signals in manufacturing processes.

- Test and Measurement: Enables accurate data acquisition in laboratory experiments and testing equipment.

- Robotics: Integrates with robotic systems to process and analyze sensor data.

- IoT (Internet of Things): Facilitates data collection and analysis in IoT applications.

Detailed and Complete Alternative Models

- SCANSTA102SM: Similar to SCANSTA101SM, but with extended input voltage range (0-10V).

- SCANSTA103SM: Provides higher resolution (16-bit) for more precise measurements.

- SCANSTA104SM: Offers faster sampling rate (5000 samples/sec) for real-time data acquisition.

(Note: The above alternative models are fictional and provided for illustrative purposes only.)

Word count: 309 words

Seznam 10 běžných otázek a odpovědí souvisejících s aplikací SCANSTA101SM v technických řešeních

Sure! Here are 10 common questions and answers related to the application of SCANSTA101SM in technical solutions:

Q: What is SCANSTA101SM?

A: SCANSTA101SM is a hardware debugging and testing tool used for embedded systems.Q: How does SCANSTA101SM help in technical solutions?

A: SCANSTA101SM helps in identifying and resolving hardware issues, improving system performance, and reducing development time.Q: Can SCANSTA101SM be used with any type of embedded system?

A: Yes, SCANSTA101SM is compatible with a wide range of embedded systems, including microcontrollers, FPGAs, and ASICs.Q: What are some key features of SCANSTA101SM?

A: Some key features of SCANSTA101SM include boundary scan testing, JTAG debugging, and in-system programming capabilities.Q: How does boundary scan testing work with SCANSTA101SM?

A: Boundary scan testing allows you to test and diagnose the connectivity of digital components on a PCB using the JTAG interface.Q: Can SCANSTA101SM be used for production testing?

A: Yes, SCANSTA101SM can be integrated into automated production testing setups to ensure the quality and reliability of manufactured products.Q: Is SCANSTA101SM software-dependent?

A: Yes, SCANSTA101SM requires software tools to control and interact with the hardware. Various software options are available depending on the specific requirements.Q: Are there any limitations to using SCANSTA101SM?

A: SCANSTA101SM may have limitations in terms of device compatibility, speed, and the complexity of the design being tested. It's important to check the specifications and capabilities before use.Q: Can SCANSTA101SM be used for real-time debugging?

A: Yes, SCANSTA101SM supports real-time debugging, allowing you to monitor and control the behavior of your embedded system during runtime.Q: Where can I find resources and support for using SCANSTA101SM?

A: You can find documentation, tutorials, and technical support for SCANSTA101SM on the manufacturer's website or through their customer support channels.

Please note that the specific details and answers may vary depending on the actual product and its documentation.